Tembarboard Introduction

Tembarboard Manufacturing Video

-

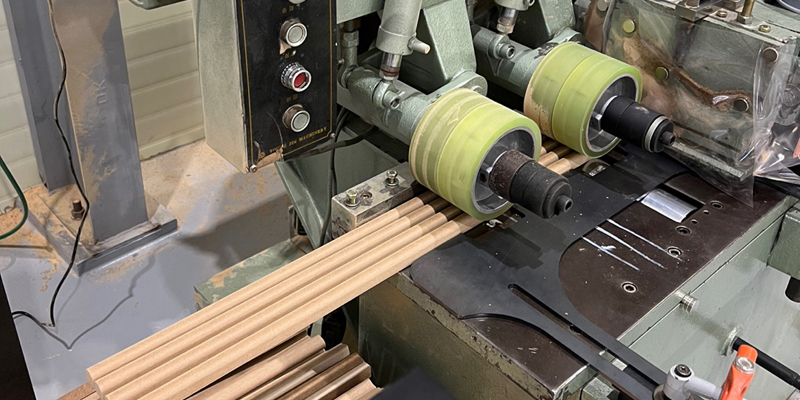

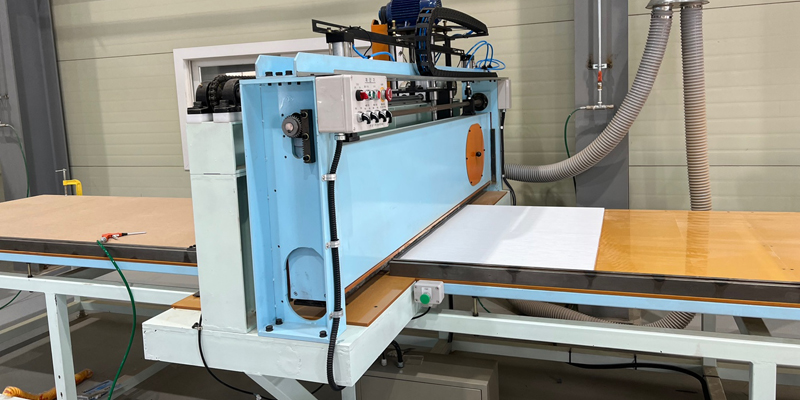

- General cutting machine

- The cross section is not cut cleanly and the tambar is ripped off.

-

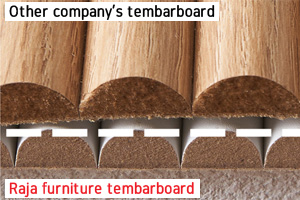

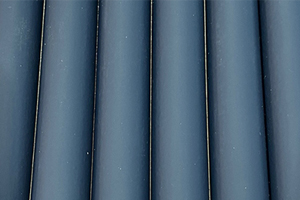

- Cutting comparison picutres

- Above : Other company’s tembarboard

Below : Raja furniture tembarboard

-

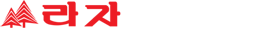

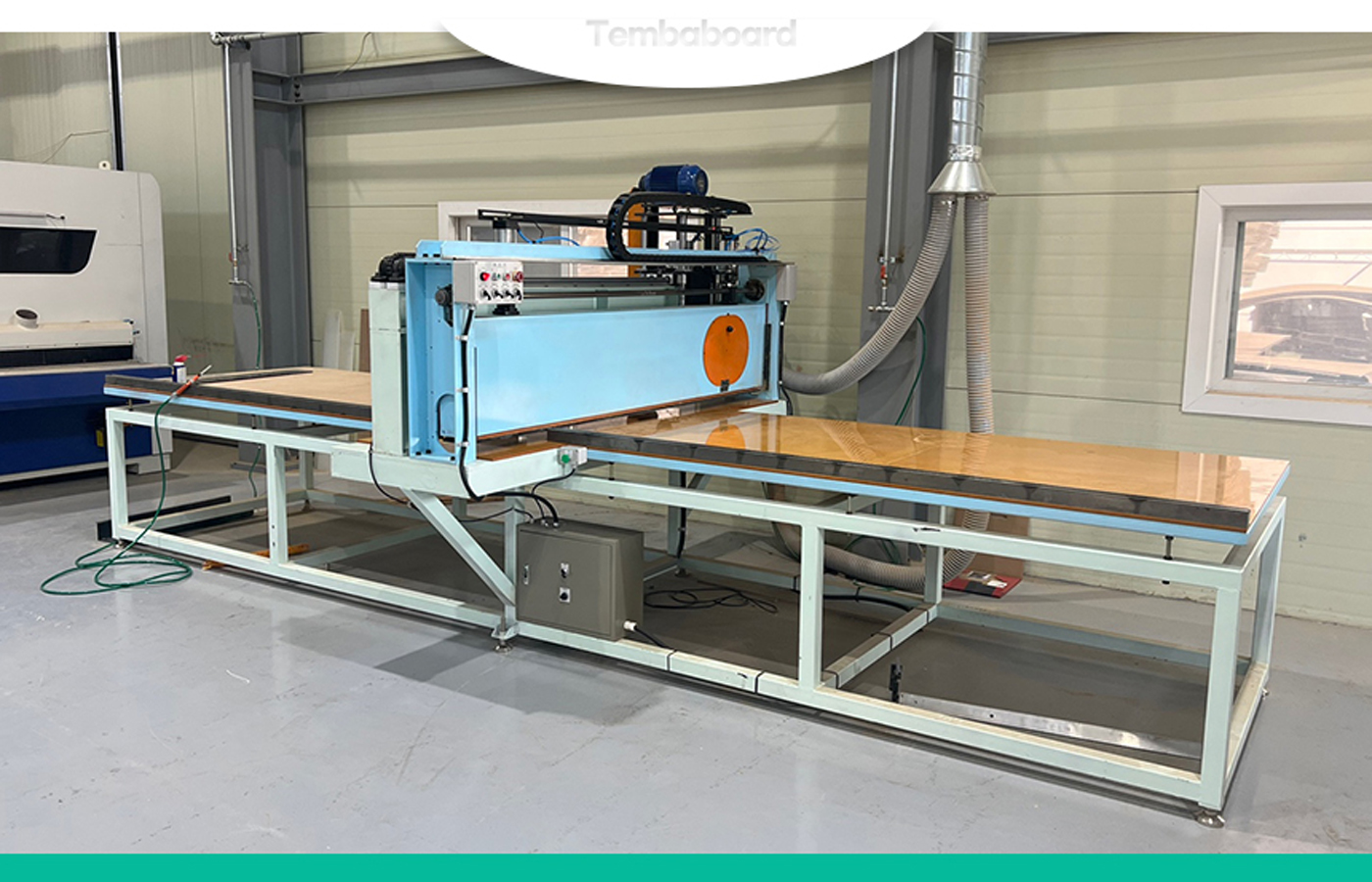

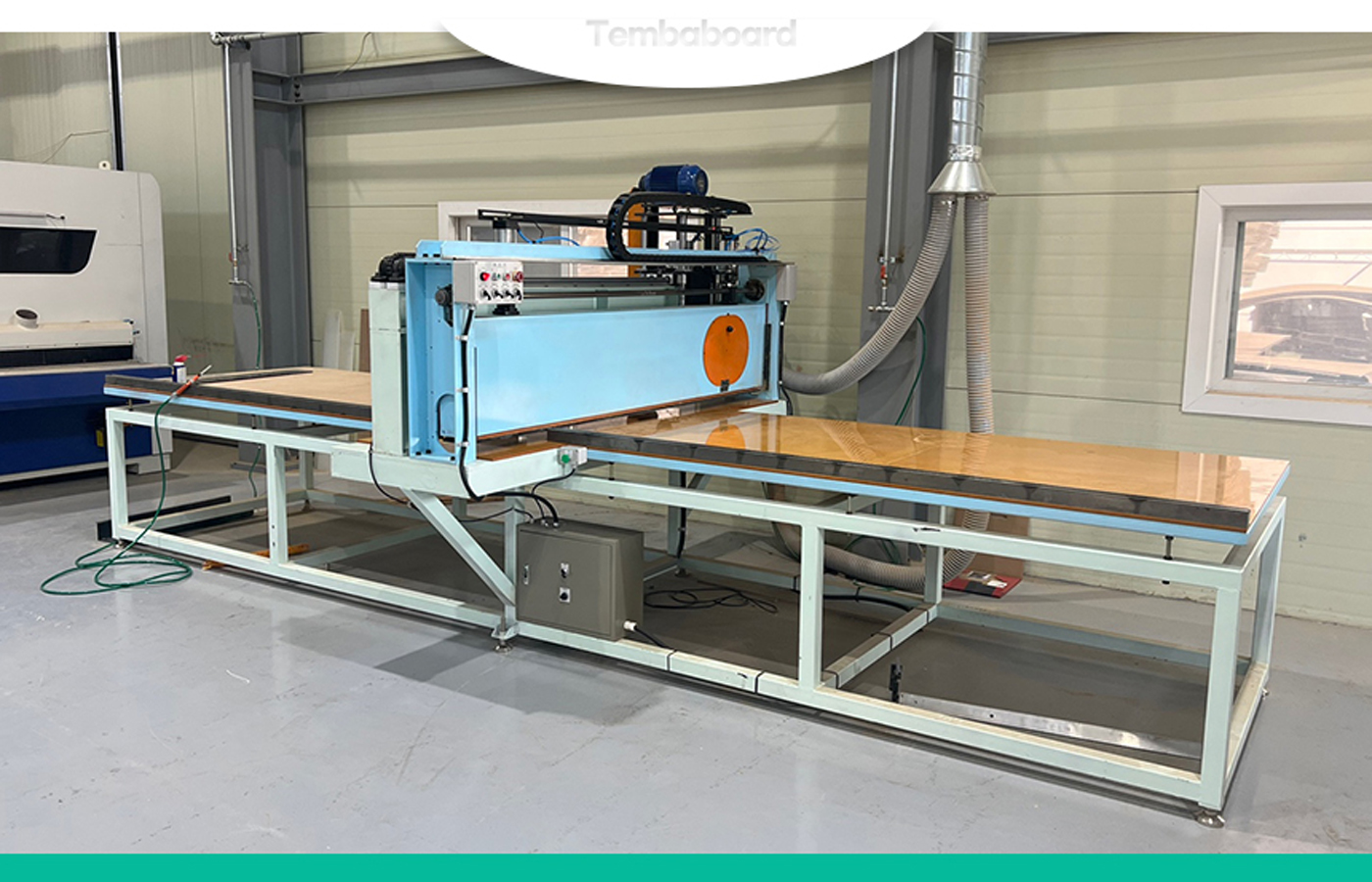

- Raja furtniture cutting machine

- The cross section is cut cleanly and there are no torn parts.

-

- General manual work

- You can see that there is a gap also it’s not regular.

-

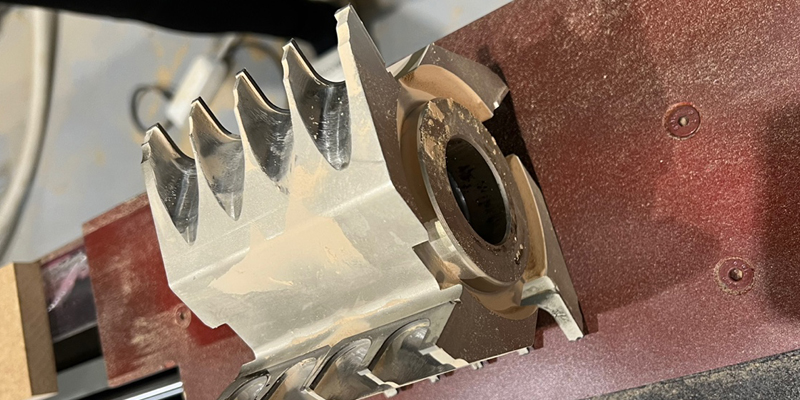

- Raja Furniture Attachment machine

- It is attached densely with a machine to maintain a certain distance.